DIY Tips for Inspecting Used Construction Equipment Before Purchase

Introduction to Inspecting Used Construction Equipment

When purchasing used construction equipment, a thorough inspection is crucial to ensure you’re making a sound investment. While new machinery guarantees optimal performance, used equipment can offer significant cost savings if chosen wisely.

This guide provides DIY tips for inspecting used construction equipment to help you make an informed purchase decision.

Exterior and Structural Inspection

Begin your inspection with the exterior and structural components. Look for visible signs of wear and damage, such as dents, cracks, or rust. These can indicate potential underlying issues that may affect the equipment's performance.

Check the frame and major structural elements for any signs of serious damage or repair. If you notice anything concerning, it might be wise to consult with a professional mechanic.

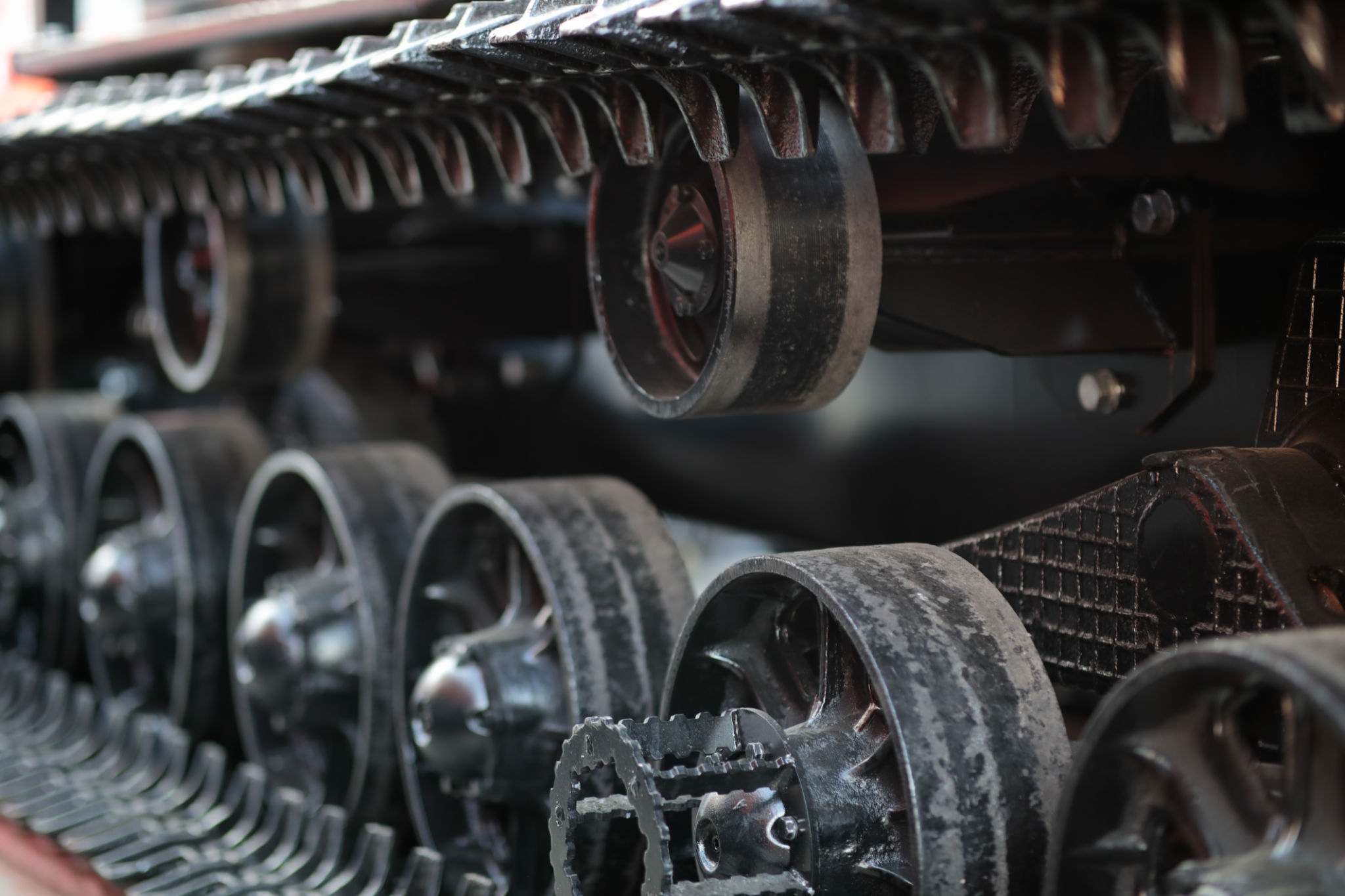

Inspecting the Undercarriage

The undercarriage is a critical part of construction equipment. Examine it for excessive wear, loose bolts, and any signs of leaks. Pay particular attention to the tracks, rollers, and idlers. These components should be in good condition without any visible damage.

Hydraulic and Engine Analysis

Next, focus on the hydraulic system and engine. Check for leaks around the hydraulic lines and cylinders. Leaks can be costly to repair and may hinder the equipment's functionality.

Start the engine and listen for any unusual noises. A well-maintained engine should run smoothly without knocking or excessive smoke. Inspect the oil and coolant levels, and check for any signs of contamination.

Fluid and Battery Check

Ensure all fluid levels, including hydraulic fluid, engine oil, and coolant, are adequate. Check the battery for any corrosion or leakage. A weak battery can lead to starting issues, which can be inconvenient on a job site.

Operational Test

Conduct an operational test to evaluate the equipment’s performance. Operate all controls and functions to ensure they respond appropriately. Test the brakes, steering, and transmission for smooth operation without delays or unusual noises.

Make sure to test the equipment under load when possible to better understand its capabilities and any potential limitations.

Documentation and Maintenance Records

Review the equipment's documentation and maintenance records. Proper documentation can provide insights into the machine's history, including past repairs and regular maintenance. This information is invaluable in assessing the equipment's current condition and longevity.

Final Considerations

While DIY inspections can be effective, consider hiring a certified inspector for a more comprehensive assessment. Their expertise can help identify issues that may not be apparent to the untrained eye, potentially saving you from costly repairs in the future.

By following these DIY tips, you'll be better equipped to evaluate used construction equipment, ensuring your purchase meets your operational needs and budget constraints.